Challenged by world-class competitors, manufacturing companies in the United States have undergone a renaissance in the last decade. The renaissance started on the shop floor with an emphasis on built-in quality, the elimination of waste, and faster throughputs. But attention quickly turned upstream to product development, where Japanese companies were outperforming U.S. competitors on nearly every measure: speed to market, design quality, product-design manufacturability, cost, and productivity. Observers concluded that the key to Japanese success, and U.S. industry's weakness, was integration—both between product design and manufacturing-process design, and with marketing, purchasing, finance, and other business functions.

A great many companies attacked the issue head on. Typical solutions were such product-development tools as quality function deployment and Taguchi methods. Companies also introduced organizational solutions; those solutions ranged from keeping the basic functional organization intact and assigning people to temporary project teams to disbanding the functional organization altogether in favor of organizing around products, as Chrysler did in the early 1990s. (Here we use the term function broadly to mean the various groups of specialized expertise required to make new models work—including the engineering specialties within the design process, such as electrical, body, or test engineering, as well as other business functions, such as manufacturing and marketing.)

The new solutions have brought substantial improvements to the companies and dramatic results in the marketplace. But they have also created problems of their own. Cross-functional coordination has improved, but at the cost of depth of knowledge within functions, because people are spending less time within their functions. Organizational learning across projects has also dropped as people rotate rapidly through positions. Standardization across products has suffered because product teams have become autonomous. In organizations that combine functional and project-based structures, engineers are often torn between the orders of their functional bosses on the one hand and the demands of project leaders on the other. As these new problems take their toll, U.S. companies are beginning to see the effectiveness of their product-development systems plateau. More important, that effectiveness seems to have leveled off far short of the best Japanese companies.

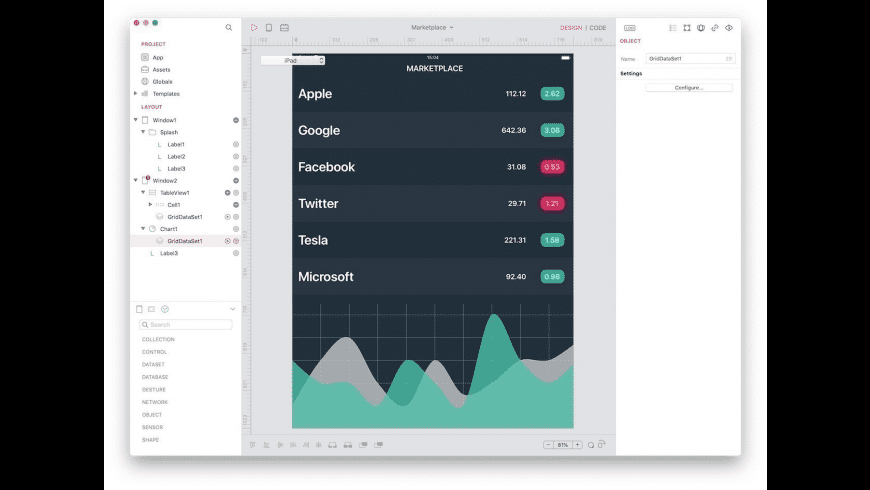

Mobile app creation process is split between the design process and the development process, Creo merges the two separated steps into a single tool which enables you to focus on what makes your app unique instead of wasting time building a nonfunctional prototype or writing the same code to perform the same most common operations. Creo 1.1.5 macOS 66 MB. I think is a MacOS tool which aims to combine the design and development process in one easy to use application. The traditional process of creating mobile applications is divided between process design and process development. Creo is a MacOS tool which aims to combine the Design and Development process into a single easy to use application.Traditional mobile app creation process is split between the design process and the development process, Creo merges the two separated steps into a single tool which enables you to focus on what makes your app unique instead of wasting time building a nonfunctional prototype. Fortunately, Creo delivers the most scalable range of 3D CAD product development packages and tools in today's market. Creo 7.0 has breakthrough innovations in the areas of generative design, real-time simulation, multibody design, additive manufacturing, and others! Chakravarthy and Y. Doz, 'Strategy Process Research: Focusing on Corporate Self-Renewal,' Strategic Management Journal, volume 13, special issue, Summer.

This article explores how one of those companies, Toyota, manages its vehicle-development process. We studied Toyota's process for five years through in-depth interviews at all levels of management. Interestingly, we found that in many ways the company does not resemble what is often considered the model of Japanese product development—it has maintained a functionally based organization while achieving its impressive degree of integration, and many of its practices are actually similar to those that U.S. companies employed during their manufacturing prime earlier in this century.

We can group Toyota's managerial practices into six organizational mechanisms. Three of them are primarily social processes: mutual adjustment, close supervision, and integrative leadership from product heads. The other three are forms of standardization: standard skills, standard work processes, and design standards. Alone, each mechanism would accomplish little, but every piece has its own role and at the same time reinforces the others, unlike many of the sophisticated tools and practices at companies in the United States, which tend to be implemented independently.

Together, the mechanisms give Toyota a tightly linked product-development system that achieves cross-functional coordination while still building functional expertise. This balance allows the company to achieve integration across projects and over time, as well as within projects. U.S. companies have concentrated on bringing the functions together within projects, but a single-minded focus on that goal can actually undermine attempts to share information across projects. Cross-functional teams, for example, work well within individual projects, but the temporary, personal nature of these teams makes it hard for them to transmit information to teams on other projects.

Toyota combines a highly formalized system with twists to ensure that each project is flexible and benefits from other projects.

Toyota, by contrast, seems to go to the opposite organizational extreme. It relies on highly formalized rules and standards, and puts limits on the use of cross-functional teams. Such rigid policies can have enormous drawbacks. To avoid those drawbacks, Toyota has added a number of twists to ensure that each project has the flexibility it needs and still benefits from what other projects have learned. The result is a deftly managed process that rivals the company's famous production system, lean manufacturing, in effectiveness.

Coordination Based on Writing

One of the most powerful ways to coordinate one's efforts with those of people in other functions is to talk to them face to face. In this manner, each party gets the other's point of view and can quickly make adjustments to find common ground. This mutual adjustment often takes the form of a meeting: a product designer and a manufacturing engineer, for example, get together to discuss the effects that a proposed design for a particular car body would have on the cost of production.

Direct contact between the members of different functions is certainly important—some say it is the essential ingredient in getting functional groups that have traditionally been at odds to work together. Indeed, many observers, managers, and engineers claim that face-to-face interaction is the richest, most appropriate form of communication for product development. Numerous companies now colocate functional experts so that interaction can occur with much greater ease and frequency. Often these companies have done away with written forms of communication because, as some claim, written reports and memos do not have the richness of information or interactive qualities needed for product development.

Meetings, however, are costly in terms of time and efficiency, and meeting time increases with colocation. Meetings usually involve limited value-added work per person, and they easily lose focus and drag on longer than necessary. Engineers in companies we've visited often complain of not having enough time to get their engineering work done because of all the meetings in their schedule.

Toyota, by contrast, does not co-locate engineers or assign them to dedicated project teams. Most people reside within functional areas and are simply assigned to work on projects—often more than one at a time—led by project leaders. By rooting engineers in a function, the company ensures that the functions develop deep specialized knowledge and experience.

In lieu of regularly scheduled meetings, the company emphasizes written communication. When an issue surfaces that requires cross-functional coordination, the protocol is first to write a report that presents the diagnosis of the problem, key information, and recommendations, and then to distribute this document to the concerned parties. Usually, the report is accompanied by either a phone call or a short meeting to highlight the key points and emphasize the importance of the information. The recipient is expected to read and study the document and to offer feedback, sometimes in the form of a separate written report. One or two iterations communicate a great deal of information, and participants typically arrive at an agreement on most, if not all, items. If there are outstanding disagreements, then it's time to hold a meeting to hammer out a decision face to face.

In such problem-solving meetings, participants already understand the key issues, are all working from a common set of data, and have thought about and prepared proposals and responses. The meeting can focus on solving the specific problem without wasting time bringing people up to speed. By contrast, at many U.S. companies, attendees often arrive at meetings having done little or no preparation. They can spend the first half of the meeting just defining the issue, and responses are shoot-from-the-hip reactions to a problem that people have had little time to think about.

Toyota takes its focused style of meeting quite seriously. One engineer we talked to showed us his schedule for the day, which included two meetings at separate times with the same group of people. When asked why he would schedule separate meetings with this group, he explained that they needed two meetings to discuss two distinct problems. It was important not to confuse the issues by combining them into one meeting.

Once the writer of the original report has consulted with all interested parties, he or she writes a final version of the report that presents all sides of the question. The overall reporting process therefore has two benefits. First, it documents and summarizes analysis and decision making in a convenient form for the rest of the organization. Second, and more important, it forces engineers in every function to gather opinions from other functions regarding the ramifications of the changes they are proposing.

Twist: Although Toyota often relies on written communication as the first line of attack in solving problems, it does not suffer from the voluminous paperwork we associate with bureaucracy. In most cases, engineers write short, crisp reports on one side of size A3 paper (roughly 11×17, the largest faxable size). The reports all follow the same format so that everyone knows where to find the definition of the problem, the responsible engineer and department, the results of the analysis, and the recommendations. The standard format also helps engineers make sure they have covered the important angles. The result is a clear statement of a problem and solutions that is accessible not only to people within a particular project but also to those working on other projects.

Writing these reports is a difficult but useful skill, so the company gives its engineers formal training in how to boil down what they want to communicate. Supervisors see to it that engineers do the appropriate groundwork to ensure that all pertinent views are taken into consideration. Toyota has also created a culture in which reading these reports is highly valued and essential to doing one's job well. Indeed, we heard about a certain Toyota executive who refused to read any report longer than two pages.

Mentoring Supervisors

In product development, supervision traditionally took place within individual functions. Electrical engineers, for example, were supervised by other electrical engineers because only they fully understood the work involved. Recently, some U.S. companies have experimented with cross-functional team-based organizations in order to force engineers to think beyond the needs of their own function. Chrysler, for example, is organized around product platforms rather than functions, and the platform team leader heads all product engineering in the platform.

Toyota, however, has not forgotten the value of instructive supervision within functions. Supervisors and higher-level managers are deeply involved in the details of engineering design. In fact, young engineers (anyone with less than ten years' experience) must usually get approval from their functional supervisors not only for the designs they propose but also for each step involved in the process of arriving at the final design.

Supervisors are deeply involved in their subordinates' work, without giving orders.

The company depends on supervisors to build deep functional expertise in its new hires—expertise that then facilitates coordination across functions. But functional supervisors also teach engineers how to write reports, whom to send the reports to, how to interpret reports from other functions, and how to prepare for meetings. Direct supervision thus works in concert with mutual adjustment in order to promote coordination.

Twist: To American eyes, such intensive supervision would seem to be a kind of meddling that stifles the creativity and learning of new engineers and other specialists. U.S. companies are moving in the opposite direction as they preach empowerment, with superiors acting as facilitators rather than bosses. But Toyota has succeeded in keeping its supervision fresh and engaging, in two ways. Like Toyota's supervisors on the factory floor, managers in product development are working engineers. Instead of merely managing the engineering process, they hone their engineering skills, stay abreast of new technology, maintain their contacts and develop new ones, and remain involved in the creative process itself. Functional engineers are not frustrated by the experience of working under someone less skilled than they are. In many U.S. companies, by contrast, engineers who rise through the ranks become managers who stop doing engineering work.

Perhaps more important, Toyota's managers seem to avoid making decisions for their subordinates. They rarely tell subordinates what to do and instead answer questions with questions. They force engineers to think about and understand the problem before pursuing an alternative, even if the managers already know the correct answer. It's not a boss-subordinate or even a coach-athlete relationship, but a student-mentor relationship.

Integrative Leaders

Perhaps the most powerful way to integrate the work of people from diverse specialties is to have a leader with a broad overview of the whole. Many U.S. companies have recently been moving toward a heavyweight-project-management structure. Heavyweight project managers coordinate all the specialists from functional departments around a common project with a common set of goals. Their authority in these matrix organizations comes from their complete control over their particular project rather than from any direct supervisory authority over the individual functions.

Toyota's equivalent is the chief engineer. Each chief engineer, based in one of Toyota's three vehicle-development centers (which oversee long-term planning across projects), maintains full responsibility for a single vehicle program but wields no direct power over the functions.

Indeed, Toyota's chief engineers come close to matching what others have described as the prototypical heavyweight project manager. Before attaining their position, they must demonstrate both exemplary technical expertise and fluency in synthesizing technical knowledge into clever, innovative designs. Toyota's managers feel strongly that only a good designer can evaluate the quality of someone else's design. Chief engineers also need to be able to conceptualize whole systems. It is one thing to understand the mechanics of a brake system and another to apply that knowledge toward an actual brake system design; but it is quite another thing to be able to conceptualize a brake system and visualize how it can be integrated with the rest of the vehicle. By contrast, a number of companies with heavyweight product managers do not have such stringent technical requirements.

All chief engineers have a small staff of 5 to 15 engineers to assist them in managing the development process and in coordinating the work of the functional specialties. The hundreds of other engineers on the project report only through the functional chain of command. The chief engineer has no formal authority over them, so he must 'persuade' them to help him realize his vision for the vehicle. One former chief engineer described the position as being the 'president of the vehicle': just as the U.S. president heads the country but has no direct authority over legislation (beyond vetoes), so a chief engineer cannot dictate what functional engineers do. But his extensive technical expertise wins him tremendous respect, even admiration, from functional engineers—a key source of his enormous informal authority.

The limits on the chief engineers' power, despite their prestige, are real, and the engineering expertise and equal rank of the general managers in charge of the functional areas can keep chief engineers from making potentially dangerous mistakes. For example, in designing a new model of the Celica sports car several years ago, the styling department suggested a longer front-quarter panel. The change would have increased the panel's extension into the top of the front door, allowing the door to curve back at the top, thereby creating an angular and more exciting look. The manufacturing engineer assigned to door panels, however, opposed the change because the altered panel would be difficult to produce.

After assessing both sides, the chief engineer for the vehicle favored the altered front panel. Nevertheless, the manufacturing engineer felt strongly that the change was unwise. If Toyota had organized around projects rather than functions, styling would likely have gotten its way, and the car might well have suffered production problems. But because the chief engineer's authority was only informal, the manufacturing engineer was able to raise the issue to the level of the general manager of manufacturing, who strongly challenged the chief engineer. After substantial argument, the two sides reached an innovative compromise that achieved the cutaway look that styling wanted with a satisfactory level of manufacturability.

Such incidents explain why one Toyota engineer, when asked what makes a good car, replied, 'Lots of conflict.' Conflict occurs when people from different functional areas clearly represent the issues from their perspective. Its absence implies that some functional areas are being too accommodating—to the detriment of the project as a whole. Still, when managers resolve conflicts through organizational influence, horse trading, or executive fiat, the results are often poor. It is the ability of chief engineers to see the broad picture clearly—and the ability of functional managers to contain the chief engineer's enthusiasm—that leads to highly integrated designs. And while the chief engineers keep individual projects on track, the autonomous functional engineers and managers ensure that knowledge and experience from other projects are not forgotten in the current one.

Twist: Chief engineers do differ in one important respect from even the best heavyweight project managers. The latter typically delegate decision making to functional teams, while retaining authority over the team's decisions and taking responsibility for implementing those decisions throughout the development process. If a heavyweight project manager doesn't like a decision, he or she can veto it. By contrast, a chief engineer takes the initiative by personally making key vehiclewide decisions. His authority over design decisions stems from the fact that the vehicle is quite clearly 'his car.' He is therefore less the manager of and more the lead designer on the overall project.

A chief engineer is less the manager of and more the lead designer on a project.

As lead designer, chief engineers design (and subsequently manage) the entire process of developing the product, and they personally articulate the vehicle concept that becomes the blueprint for the entire program. That concept includes the major dimensions of the vehicle; decisions on such major systems as the transmission; the variety of models to be offered; the characteristics of the target customer; sales projections; and targets on weight, cost, and fuel economy. Chief engineers integrate the work of the functions by planning how all the parts will work together as a cohesive whole, soliciting input from the various engineering, manufacturing, and marketing functions, of course. Once a chief engineer has designed the overall approach for a car, the different functions fill in the technical details that are required to realize the vehicle concept.

Some of the remaining integration problems at U.S. Byword 2 0 – minimalist typing interface. companies may in fact stem from a lack of precisely this kind of system design. Even companies with able heavyweight product managers tend to jump directly from product concept to the technical details of engineering design. They bypass, without going through, the very difficult but important task of designing the overall vehicle system: planning how all the parts will work together as a cohesive whole before sweating the fine details. At Toyota, the chief engineer provides the glue that binds the whole process together.

Standard Skills

Every company depends on highly skilled engineers, designers, and technicians to bring a product to market. Organizations can coordinate their activities by giving each person within a specialty the same set of skills to accomplish his or her tasks. When we know what to expect of others because they are trained in a certain way, we can request specific services with relatively little effort in coordination. In engineering, most U.S. companies rely heavily on universities or specialized training companies to provide their people with the skills needed to do their jobs.

Toyota, by contrast, relies primarily on training within the company. It views training as a key competency, worth developing internally rather than outsourcing. Engineers receive most of their training through the intensive mentoring involved in direct supervision, although the company also runs a training center with instructors who are experienced Toyota engineers. The process not only develops excellent engineers but also teaches new hires Toyota's distinct approach to developing the body, chassis, or other systems in a vehicle.

Additionally, Toyota rotates most of its engineers within only one function, unlike U.S. companies, which tend to rotate their people among functions. Body engineers, for example, will work on different auto-body subsystems (for example, door hardware or outer panels) for most, if not all, of their careers. Because most engineers rotate primarily within their engineering function, they gain the experience that encourages standard work, making the outputs of each functional group predictable to other functions. In addition, rotations generally occur at longer intervals than the typical product cycle so that engineers can see and learn from the results of their work.

That consistency over time means that the company's engineers in the manufacturing division, for example, need to spend less time and energy communicating and coordinating with their counterparts in design because they learn what to expect from them. Indeed, Toyota firmly believes that deep expertise in engineering specialties is essential to its product-development system. We often heard such comments as, 'It takes ten years to make a body engineer' in our conversations with the company's managers. In short, the widely held notion that Japanese companies rotate their personnel broadly and frequently simply does not apply to Toyota.

Twist #1: Rotating locally and building functional expertise would seem to create rigid functional boundaries, or chimneys, in which engineers work only to be the best in their function. An electrical engineer, for example, might aim to develop the most elaborate electrical design possible, without thinking about how that design will work with the rest of the vehicle. But we have found that the so-called chimney effect is not the result of young engineers being too loyal to their functions or too narrow-minded about what cars need. Rather, it is usually the result of experienced engineers and managers hoarding their knowledge, which becomes the basis of their power in an organization rooted in functions.

A chief engineer is less the manager of and more the lead designer on a project.

As lead designer, chief engineers design (and subsequently manage) the entire process of developing the product, and they personally articulate the vehicle concept that becomes the blueprint for the entire program. That concept includes the major dimensions of the vehicle; decisions on such major systems as the transmission; the variety of models to be offered; the characteristics of the target customer; sales projections; and targets on weight, cost, and fuel economy. Chief engineers integrate the work of the functions by planning how all the parts will work together as a cohesive whole, soliciting input from the various engineering, manufacturing, and marketing functions, of course. Once a chief engineer has designed the overall approach for a car, the different functions fill in the technical details that are required to realize the vehicle concept.

Some of the remaining integration problems at U.S. Byword 2 0 – minimalist typing interface. companies may in fact stem from a lack of precisely this kind of system design. Even companies with able heavyweight product managers tend to jump directly from product concept to the technical details of engineering design. They bypass, without going through, the very difficult but important task of designing the overall vehicle system: planning how all the parts will work together as a cohesive whole before sweating the fine details. At Toyota, the chief engineer provides the glue that binds the whole process together.

Standard Skills

Every company depends on highly skilled engineers, designers, and technicians to bring a product to market. Organizations can coordinate their activities by giving each person within a specialty the same set of skills to accomplish his or her tasks. When we know what to expect of others because they are trained in a certain way, we can request specific services with relatively little effort in coordination. In engineering, most U.S. companies rely heavily on universities or specialized training companies to provide their people with the skills needed to do their jobs.

Toyota, by contrast, relies primarily on training within the company. It views training as a key competency, worth developing internally rather than outsourcing. Engineers receive most of their training through the intensive mentoring involved in direct supervision, although the company also runs a training center with instructors who are experienced Toyota engineers. The process not only develops excellent engineers but also teaches new hires Toyota's distinct approach to developing the body, chassis, or other systems in a vehicle.

Additionally, Toyota rotates most of its engineers within only one function, unlike U.S. companies, which tend to rotate their people among functions. Body engineers, for example, will work on different auto-body subsystems (for example, door hardware or outer panels) for most, if not all, of their careers. Because most engineers rotate primarily within their engineering function, they gain the experience that encourages standard work, making the outputs of each functional group predictable to other functions. In addition, rotations generally occur at longer intervals than the typical product cycle so that engineers can see and learn from the results of their work.

That consistency over time means that the company's engineers in the manufacturing division, for example, need to spend less time and energy communicating and coordinating with their counterparts in design because they learn what to expect from them. Indeed, Toyota firmly believes that deep expertise in engineering specialties is essential to its product-development system. We often heard such comments as, 'It takes ten years to make a body engineer' in our conversations with the company's managers. In short, the widely held notion that Japanese companies rotate their personnel broadly and frequently simply does not apply to Toyota.

Twist #1: Rotating locally and building functional expertise would seem to create rigid functional boundaries, or chimneys, in which engineers work only to be the best in their function. An electrical engineer, for example, might aim to develop the most elaborate electrical design possible, without thinking about how that design will work with the rest of the vehicle. But we have found that the so-called chimney effect is not the result of young engineers being too loyal to their functions or too narrow-minded about what cars need. Rather, it is usually the result of experienced engineers and managers hoarding their knowledge, which becomes the basis of their power in an organization rooted in functions.

To prevent the chimney effect's political conflicts, engineers at the bucho level are regularly rotated to areas outside their expertise.

To avoid such political conflict, Toyota takes care to rotate most of its senior people broadly. Engineers at the bucho level—which usually means the head of a functional division (for example, power-train engineering for front-wheel-drive passenger cars) with at least 20 years' experience—typically rotate widely across the company to areas outside their expertise. Such moves force buchos to rely heavily on the experts in their new area, building broad networks of mutual obligation. At the same time, buchos bring their own experience, expertise, and network of contacts that they can use to facilitate integration.

Twist #2: Buchos (and chief engineers) encourage their people to see the needs of the product as a whole, but Toyota also keeps design engineers aware of the ramifications of their decisions throughout the development process. These engineers retain responsibility for their parts of the car from the concept stage to the start of full production. A door-systems engineer, for example, works with stylists to determine the concept of the door and then develops the detailed design by working with production engineers and outside suppliers. The engineer also goes to the factory to be part of the launch team as the vehicle ramps up to full production.

Flexible Work Standards

The stereotypical bureaucratic way of coordinating work processes is to specify in detail the content of each step in the process. Tasks are preprogrammed so that one group knows what to expect from another and when to expect it, with little or no communication required. Factories use this kind of coordination extensively, standardizing the tasks at each workstation to ensure that the work is done consistently and in a set amount of time. All the workstations can then be easily coordinated by a schedule.

Many U.S. companies have tried to apply this concept to product development, notably General Motors with its four-phase process. A special team at GM defines the process in great detail, telling each department what it needs to do when, whom to send results to, what format the information should take, and so on. The plan for the styling function alone covers the length of one wall in a sizable conference room. The four-phase process is almost never followed as its authors envisioned, however, because the process is so detailed that every vehicle program has exceptions that force designers to deviate from the prescribed process—the real world resists such intensive planning. In addition, a separate group develops and maintains the details of the standard process; as a result, the people who must follow the process do not have ownership of it, and the prescribed processes are not likely to be truly representative of the actual one. Indeed, the four-phase process seems to do little to shorten cycle times or to bring other benefits that such thorough planning aims to produce. Companies such as General Motors face a dilemma: the more they attempt to define the process of product development, the less the organization is able to carry out that process properly.

Toyota, by contrast, has successfully standardized much of its development process. Product-engineering departments follow highly consistent processes for developing subsystems within a vehicle. Routine work procedures—such as design blueprints, A3 reports, and feedback forms for design reviews—are also highly standardized. The overall process of developing a vehicle follows regular milestones. Indeed, the suppliers we visited in Japan could describe from memory Toyota's vehicle-development process because it is so consistent from model to model. Every model has a concept, styling approval, one or two prototype vehicles, two trial production runs, and finally a launch; and suppliers know the approximate timing of each event. (For more on how Toyota uses standards to coordinate its work with suppliers, see 'A Second Look at Japanese Product Development,' by Rajan R. Kamath and Jeffrey K. Liker, HBR November–December 1994.)

Twist #1: How does Toyota avoid the pitfalls that other companies have experienced with work standards? When you talk specifics with Toyota engineers—such as how many prototypes are built and tested, when designs are finalized, or how long a particular phase takes—the response is typically that it varies case by case. The actual standardized work plans are kept to a minimum; they often fit on a single sheet of paper. The basic process in the eyes of the participants is very consistent from model to model, but the implementation of the concept is individually designed for each vehicle program. Intense socialization of engineers through on-the-job training creates a deep understanding of every step, as well as a broad understanding of the expectations at milestones and final deadlines. The simplified plans allow flexibility, common understanding, and continuous improvement, while hard deadlines keep the project on track. The company thus gains the efficiencies offered by standards without stifling its engineers. The standards also save product developers the trouble of reinventing a new process for each individual project.

Twist #2: Another difference is that the standard work procedures are maintained by the people and departments that use them, not by a centralized staff that may be tempted to standardize for the sake of standardization. As a result, standards are more likely to be simple and to the point, relevant and up-to-date. They are therefore more likely to be followed. In addition, the people who use the standards understand their intent, so deviations are perfectly permissible as long as consistency (and thus predictability for other functions) is maintained. At Toyota, developing the product and designing standard development processes are considered to be inseparable tasks.

Living Design Standards

In the past, product developers often used standardized product rules to guide their work. Many companies, however, seem to have shied away from design standards in recent years. Engineers at automakers in the United States have told us time and again that design standards are largely ignored at their companies. Arguing that technology is changing too fast for standards to be valuable, they boast about 'starting from a clean sheet of paper' in new product-development projects. (Test engineers, of course, rely on standards to ensure that the final product meets government regulations and other requirements, but those guidelines concern the product's function instead of providing information for the product's design.) Design standards appear to be archaic or stifling to companies that depend on innovation for success.

Toyota, however, still maintains voluminous books of engineering checklists to guide design work. These checklists act as the first cut at designing manufacturable products that use common parts across platforms. Engineering checklists contain detailed information concerning any number of aspects, including functionality, manufacturability, government regulations, and reliability. The styling department, for example, has a checklist for the license-plate well that contains plate dimensions, bolt hole locations, regulations on tilt angles and illumination for various world markets, and restrictions on curvature radii. And every part of the car body has a separate manufacturing checklist that shows what angles will produce a good part, what kinds of interfaces avoid problems in assembly, and other guidelines.

Engineers use the checklists to guide the design throughout the development process. The checklists are particularly important for the intensive design reviews that every vehicle program undergoes. Hundreds of engineers come together to study a vehicle or prototype at key junctures, looking for problems and opportunities for improvement. What keeps these extremely large meetings from becoming chaotic is that all engineers come with a list of all the items they need to verify from their perspective. If the design conforms to the checklist, the part is highly likely to meet a certain level of functionality, manufacturability, quality, and reliability. If it does not, discrepancies between the checklists and the design become the focal points of discussion among the divisions. The design review checklists are another example of using written forms of communication to improve face-to-face meetings.

Once in place, design standards add predictability across vehicle subsystems, and between product design engineers and manufacturing engineers. The engineer responsible for audio speakers, for example, can take advantage of existing specifications for door sizes and door components and can begin designing speakers without coordinating directly with the other engineers working on door components. As a result, Toyota is able to bring new products to market quickly—as it demonstrated with the RAV4 mini-sport-utility vehicle, which was brought to market in 24 months, carved out a new product niche in Japan, but still drew on existing design standards for 80% of its makeup.

Engineering checklists also facilitate organizational learning across generations of vehicles. Toyota trains its engineers not only to record product histories but also to abstract from that experience in order to update existing capabilities. When an engineer learns something new, the knowledge can be incorporated into the checklist and then applied across the company to every subsequent vehicle. Those lessons reside with the organization, not in one person's head. If an engineer leaves, the knowledge he or she has gained is captured in the checklists and remains with the company. Just as standardization is the key to continuous improvement on the factory floor, standards are the basis for continuous improvement in engineering design.

When an engineer learns something new, the knowledge is incorporated into a checklist and applied to all the company's vehicles.

Twist #1: Again, such standardization smacks of the kind of bureaucratic approach that U.S. companies seem bent on avoiding. But rather than presenting design rules that have been imposed by a central staff, the checklists explicitly define current capabilities as understood by the responsible designers. They are living documents: product and manufacturing engineers update the standards with every vehicle program. New information is quickly and efficiently disseminated throughout the organization and into interfacing divisions, without any meetings taking place.

Twist #2: Toyota's continuous and overlapping product cycles also help keep standards fresh. The company launches new vehicles on a regular basis, several times every year. It also has annual product renewals, and a major model change every three to four years, unlike other companies that stretch out their product cycles. Accordingly, standards are revisited every couple of months (as opposed to being used once and then put away for a couple of years); they never become outdated. The frequent changes to the checklists also give engineers continual opportunities to develop and hone their skills.

Managing Product Development as a System

Together, these six mechanisms make up a whole system, each part supporting the others. Mentoring supervision serves mainly to build functional expertise, but it also teaches young engineers how to write and interpret reports, work with chief engineers, and understand and use standards. The chief engineer's prestige reinforces the importance of expertise while it also balances out the functional bent of the other engineers. The chief engineer also promotes mutual adjustment by providing the working instructions for each vehicle program and by resolving cross-functional disagreements.

For their part, the three types of standards interact and support one another to boost the pace of development; at the same time, they allow flexibility and build Toyota's base of knowledge. Without the other mechanisms providing reinforcement, each mechanism would not be nearly as effective. (See the exhibit 'How the Coordinating Mechanisms Work Together.')

Indeed, the two halves of Toyota's system—social processes and standards—interact in powerful ways. The functional organization, with its intensive mentoring, trains and socializes engineers in ways that foster in-depth technical knowledge and efficient communication. Without deep tacit knowledge about how to develop products, standardization would become a bureaucratic nightmare. In turn, the common use of the different standards makes all functions automatically aware of the constraints imposed by interfacing groups and gives focus to reports and meetings. Toyota shows that companies do not need to choose between functional depth and cross-functional coordination—each can facilitate the other within the right environment.

Toyota's balanced approach also benefits from basic company policies that provide a foundation for the whole system. With a stable and long-term workforce, the company can afford to invest heavily in training and socializing its engineers; it knows that the investment will pay off for many years. The company also places great emphasis on satisfying customers. Most of its engineers in Japan, for example, are required to sell cars door to door for a few weeks in their first year of hire. Both factors help discourage the functional loyalties that might otherwise afflict a company with Toyota's structure.

These synergistic interactions give Toyota's system its stability and power. They enable the auto-maker to integrate across projects as well as within them. Design standards, for example, facilitate integration across functions while promoting the use of common components in simultaneous projects, and provide a ready base of knowledge for the next generation of products.

Implications for Other Companies

Toyota's mix of practices may not be right for other industries, or even for other companies in the auto industry. Different environments, different corporate cultures, and different circumstances mean that a company's product-development system must be uniquely designed to suit its distinct needs. Indeed, Toyota's system is not necessarily perfect even for Toyota. Although the company has succeeded mightily with its new products in mass-market sedans and luxury cars—two well-defined segments of the marketplace—it has reacted late to the recent major shifts in consumer demand: first to mini-vans and then to sport-utility vehicles. So design standards and internal socialization, for example, may make for nimble and innovative product development, but perhaps at the cost of discouraging some big leaps in thinking.

Nevertheless, we believe that Toyota's system has important implications for other companies. First, integrated product-development processes should be developed and implemented as coherent systems. Individual best practices and tools are helpful, but their potential can be fully realized only if they are integrated into and reinforce the overall system. Toyota was fortunate in that it was able to develop its system over decades through an incremental, almost unconscious, process of taking good ideas and adapting them to the existing structure. Other companies that conclude they are going down the wrong track and need a major overhaul of their product-development systems do not have the luxury of developing their system gradually over time. They will need to be much more conscious of designing a coherent system.

Second, well-designed systems should balance the demands of functional expertise and cross-functional coordination. The chart 'How Toyota Avoids Extremes' describes features of the two opposing sides: the chimney extreme, characterized by strong functional divisions, and the committee extreme, characterized by broad-based decision making and weak functional expertise. Toyota, for example, uses both written forms of communication and face-to-face contact to the extent that each is useful and efficient.

How Toyota Avoids Extremes

Achieving the proper balance, however, is no easy task. Many of Toyota's current practices—such as an emphasis on written communication, design standards, and the chief engineer—seem to have been standard practice in the United States in the 1950s and earlier. But in the 1960s and 1970s, as U.S. automakers neglected their development processes, systems that were once sound and innovative gave way to bureaucracy, internal distrust, and other distractions that brought the companies close to the chimney extreme. In reaction, those companies seem to have swung toward the other end of the spectrum. Results in the short term have been encouraging, but the deficiencies of the committee extreme may well appear soon. Some companies are discovering them already.

The key is to strike the appropriate balance for one's situation. It may be perfectly appropriate in some circumstances to rely almost solely on meetings for communication and problem solving or to abandon standard procedures completely. But such practices are not good for all organizations at all times. They are not panaceas, and they do have significant drawbacks. One must weigh the benefits and drawbacks of a particular practice, including how it contributes to all aspects of integration (including integration across projects) and how it affects other parts of the system.

Creo 1 1 6 – Combine Design And Development Processes Flow Chart

Finally, the success of Toyota's system rides squarely on the shoulders of its people. Successful product development requires highly competent, highly skilled people with a lot of hands-on experience, deep technical knowledge, and an eye for the overall system. When we look at all the things that Toyota does well, we find two foundations of its product-development system: chief engineers using their expertise to gain leadership, and functional engineers using their expertise to reduce the amount of communication, supervision, trial and error, and confusion in the process. All the other coordinating mechanisms and practices serve to help highly skilled designers do their job effectively. By contrast, many other companies seem to aspire to develop systems 'designed by geniuses to be run by idiots.' Toyota prefers to develop and rely on the skill of its personnel, and it shapes its product-development process around this central idea: people, not systems, design cars.

Creo 1 1 6 – Combine Design And Development Processes Examples

Creo 1 1 6 – Combine Design And Development Processes Ppt

morgan

🍏MacOS Supplier🍏Creo 1 1 6 – Combine Design And Development Processes Involves

Creo Pro 2.0.6

Creo is a MacOS tool which aims to combine the Design and Development process into a single easy to use application. Traditional mobile app creation process is split between the design process and the development process, Creo merges the two separated steps into a single tool which enables you to focus on what makes your app unique instead of wasting time building a nonfunctional prototype or writing the same code to perform the same most common operations. Thanks to our CreoKit we always use NATIVE components and classes, no simulated or web based code is used

What's New in 2

Redesigned User Interface

A totally redesigned interface makes the design process more intuitive than ever before. Now supporting Dark and Light Mode in macOS Mojave.

Flexible Layout

Build flexible layouts on any platform with a highly optimized layout engine designed with speed, size, and ease of use in mind.

Swift Exporting

Creo exporter's mission is being able to generate a readable and simple to maintain native project (ie. for XCode) that any developer can open and build with native tools.

OS X 10.11+

Download